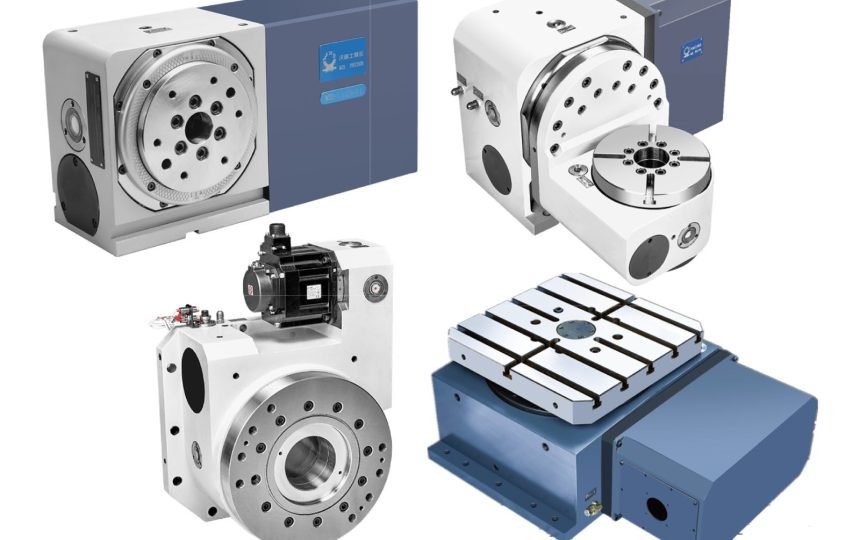

Sourcing CNC 4Axis & 5Axis Rotary Tables in China

In the world of precision machining, CNC 4-axis and 5-axis rotary tables are essential components for achieving complex geometries and high-accuracy manufacturing. Sourcing these advanced rotary tables from China offers a cost-effective solution, but it requires a deep understanding of key performance parameters, compliance standards, and quality assurance processes. At Direct Sourcing China, we specialize in sourcing and developing CNC rotary tables that meet the highest standards of quality, precision, and reliability. In this article, we’ll explore the key parameters to consider when sourcing these devices, as well as the compliance and certifications required to ensure market readiness.

Why Choose Direct Sourcing China for CNC Rotary Tables?

1. Direct Factory Partnerships

- We collaborate directly with manufacturers, ensuring better pricing, faster lead times, and greater control over quality.

- Our close relationships with factories allow us to customize products to meet your specific requirements.

2. Full Product Qualification

- We conduct rigorous testing and evaluation to ensure every rotary table meets the required performance and quality standards.

- Our team verifies key parameters such as accuracy, load capacity, and durability to ensure optimal performance.

3. Compliance Assurance

- We ensure all products comply with global standards and certifications, including CE, ISO, and more.

- Our expertise in navigating complex regulations saves you time and ensures market readiness.

4. End-to-End Support

- From initial design and prototyping to mass production and quality control, we handle every step of the process.

- We provide detailed documentation and support to ensure smooth product acceptance and integration.

5. Cost-Effective Solutions

- By leveraging our direct factory partnerships, we deliver high-quality products at competitive prices, giving you a significant edge in the market.

The Top Innovator in Precision Rotary Tables in China

We cooperate the leading precision rotary table manufacturer providing solutions for aerospace, automotive manufacturing and turbines—and more. With our roller cam drive technology, we guarantee that no-backlash performance for demanding operation. We harness cutting-edge technology to develop unique solutions for our clients and consistently deliver the best results.

Key Parameters for CNC 4-Axis & 5-Axis Rotary Tables

When sourcing CNC rotary tables, it’s essential to evaluate the following key parameters to ensure optimal performance and customer satisfaction:

Repeatability: Ensures consistent performance over multiple cycles (e.g., ±0.0005°).

Dynamic Load: The load capacity during operation, including rotational forces.

Torque: The rotational force the table can generate, critical for machining heavy or complex parts.

Bearings: Precision bearings for smooth operation and long-lasting performance.

Mounting Options: Flexible mounting configurations to fit different machine setups.

Cooling Systems: Integrated cooling to prevent overheating during prolonged use.

Automation Compatibility: Support for automated loading and unloading systems.

Compliance and Certifications for CNC Rotary Tables

To ensure your CNC rotary tables meet global market requirements, they must comply with the following standards and certifications:

FCC (USA): Ensures the device does not emit harmful electromagnetic interference.

ISO 230 (for Machine Tools): Specifies testing methods for machine tool accuracy and performance.

UL (USA): Ensures safety and compliance with U.S. standards

Our Advice:

Charlie

Contact Information

Contact Solutions

Need Help? Call Us Now

8615728597570